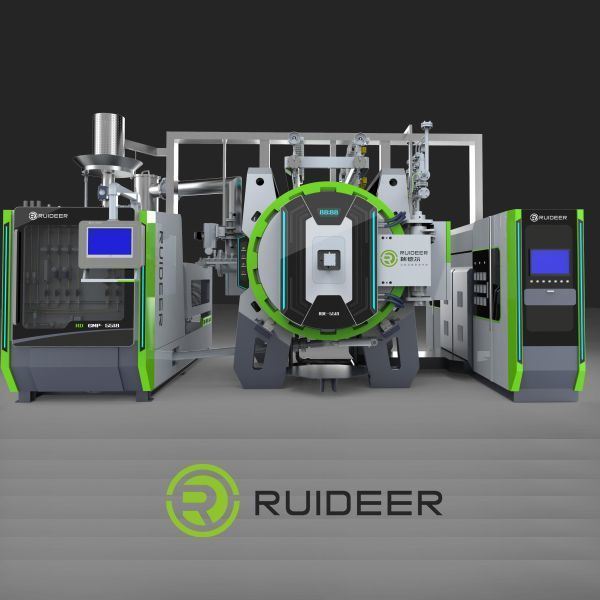

Gas Pressure Sintering GPS furnace with energy cost reducing 25%

Zhuzhou Ruideer Intelligent Thermal Equipment Co.,Ltd located in Ruideer Technology Park,Tianyuan District,Zhuzhou Hunan Province,founded in 2011,covering an area of more than 19,000 square meters.

At present,Ruideer has developed two core technologies of “high temperature &high pressure”and “chemical vapor deposition” with supplying vacuum sintering furnace and CVD coating furnace.

Our main products including:GPS furnace,MIM vacuum sintering furnace,ceramic silicon carbide/nitride sintering furnace,silicon carbide coating furnace,cemented carbide cutting tool CVD coating furnace and the turnkey solution for the cemented carbide cutting tool(From RDP powder,press machine,sinter furnace,cuuting machine,laser machine,metalgraphic testing instruments,sandblasting matchine,ultrosonic cleaning machine to CVD coating furnace).

The Gas Pressure Sintering Furnace(GPS furnace) has been awarded National Manufacturing Champion Product,widily used in cemented carbide,non-cermets,semiconductor,aerospace,automobile manufacturing,weapons and other fields,exported to the US,Russia,Japan,EU,Ukraine,South Korea,Vietnam and other countries,which making Ruideer a well-known brand in the industry.

The main parameters for the equipment:

| Furnace Type |

Horizontal type(Max Working pressure:58bar/98bar |

| RDE-3312-6 |

RDE-4412-6 |

RDE-5512-6 |

RDE-5518-6 |

| Usable Space (W*H*L) |

300*300*1200mm |

400*400*1200mm |

500*500*1200mm |

500*500*1800mm |

| Max.Charge Load |

300kg |

500kg |

1200kg |

1500kg |

| Power Rating |

320KVA |

320KVA |

430KVA |

600KVA |

| Heating Zone |

2/3 Zones |

3 Zones |

3 Zones |

3 /4 Zones |

| Cooling time |

≤5h |

≤6h |

≤7h |

≤8h |

|

Empty furnace, cooling from sintering temperature 2100℃ to 100℃.

(water temperature≤26℃, water pressure 2-3bar, 55bar(95bar)≤Ar pressure≤58bar(98bar).

|

| Service Life |

20years/6000furnace cycles |

| Max. Working Temp |

1650℃ |

| Temperature Measurement |

Special design High temperature W-Re5/26 Thermocouple |

| Max Vacuum Degree |

1Pa (under cold, empty, dry furnace) |

| Leakage Rate |

3Pa/h (Average value under cold, empty, dry furnace) |

| Input gas |

N2, Ar, |

| Functions |

Automatic Positive Pressure, Negative Pressure Leak Detection

Vacuum Sintering

Partial Pressure Sintering (Static, Dynamic)

Pressure Sintering

Rapid Cooling

Fully-automatic control & Safety interlock& Breakpoint continuing heating & Wireless remote control& Self-diagnosis

|

The special feature of the GPS process is a sequence of dewaxing at low pressure, sintering at normal pressure and -after a status is reached with only closed pores being present in the material - sintering at a high pressure, which results in a further densification and faster elimination of the remaining pores. Therefore materials produced in the GPS technology show in general mechanical properties (hardness, strength, Weibull-modulus, fracture toughness) which are superior to those of pore-free materials produced by the conventional sintering method.

The devices are particularly suitable for sintering such types of ceramics or metals, which tend to decomposition at elevated temperatures or which do not sinter to high densities in standard sintering operations. This process has not the limitations with respect to the shape of the manufactured parts as in hot pressing and it is also an advantageous alternative to the more costly HIP-process.

Available volume: 54 dm³ to 500 dm³ at 1650°C / 10 MPa (N2 or Ar atmosphere)

Applications of GPS plants:

Sintered silicon nitride and sialon with excellent mechanical properties (e.g. cutting tools, turbocharger rotors, engine components)

Silicon carbide (mechanically heavy strained parts in corrosive environments etc.)

Super alloys (mechanically strained parts in high-temperature applications)

Hard metals, especially cemented carbides with low content of Cobalt and for high-quality grades with optimum mechanical properties.

Composite materials in general

A very promising application of this technique is the production of serial parts made of SSN for the automobile industry.

How to achieve energy-saving effects?

Ridder’s GPS furnace features an 800L effective working space, 80% larger than mainstream products. This expanded capacity enables high-volume sintering in a single batch, reducing energy waste from frequent startups/shutdowns and spreading energy costs across more workpieces, laying the foundation for energy savings.

The core rapid cooling system is a key energy-saving breakthrough. It shortens the cooling time of a nearly 1500°C furnace from 6-10 hours (traditional) to around 30 minutes, cutting invalid energy consumption during non-sintering stages and minimizing heat loss to the environment.

The furnace adopts high-performance composite insulation layers to significantly reduce heat leakage. Equipped with zone-independent heating units, it precisely adjusts power based on temperature needs of different furnace areas, avoiding energy redundancy from overall heating.

Integrated advanced automated control systems monitor and regulate temperature, pressure, and other key parameters in real time. By dynamically optimizing heating rates and holding times based on material requirements, it eliminates energy waste from parameter fluctuations and human errors.

More about differences between Sinter HIP Furnace and Gas Pressure Sintering Furnace

Main functions description:

- Automatic leak detection of positive and negative pressure before opening the furnace;

- Ar carrier gas differential pressure dewaxing function;

- Ar carrier gas differential pressure dewaxing function;

- H2 micro positive dewaxing function;

- Vacuum sintering function;

- Partial sintering function;

- Static partial pressure sintering function;

- Dynamic partial pressure sintering function;

- Gas atmosphere product processing function;

- Pressure sintering function;

- Pressure sintering function;

- Fully automatic control function;

- Safety interlock function;

- Break point reheating function;

- Wireless remote diagnosis function;

Equipment strengths:

- The equipment has the function of continuous heating at break point, automatic dewaxing function, wireless remote diagnosis function, and low temperature test function;

- The equipment vacuum main pipeline and dewaxing system are equipped with filters (patented products) to prevent dust and impurities from polluting the pump oil, and extend the oil change time and the service life of the pump unit.

- Convenient and intelligent: The control interface of the sintering furnace can be monitored through the mobile phone, and the operation status of the equipment can be controlled and understood anytime and anywhere. Fully automatic one-key operation function, one person can supervise multiple devices, intelligent production, and can be connected to ERP management system.

- Complete after-sales service system: provide 7×24 hours telephone hotline. After receiving the customer's fault notification, a solution will be proposed within 2 hours, and if it is urgent case which needs on site maintenance, technical crew will arrive within 12 hours after boarding the plane. With experienced professional after-sales service personnel, they are not only responsible for the installation and commissioning of the company's products, but also complete the after-sales and maintenance of sintering furnaces for both domestic and foreign manufacturers.

- Convenient service: Users can test products at the site of Ruideer if they have needs. The company's production site has conditions for hot pressurization.

- Quick installation: Under the condition that the user's water, electricity, and gas are in place, installation, debugging, and production can be completed within 20 days.

- Company testing equipment: In order to ensure the quality of the products, Ruideer is equipped with imported helium mass spectrometer leak detectors, which are used to test the sealing surfaces of the equipment before leaving the factory to prevent small leaks and achieve a perfect sealing state. At the same time, it is also equipped with cobalt magnetometer and coercivity magnetometer professional precision testing equipment (currently the sintering furnace equipment manufacturer, only equipped by Ruideer), to meet customers' rapid pre-acceptance at the production site, and to control the sintered furnace The sample block is tested, and the performance results of the furnace control plate sample block can be tested in time, and the detection level has reached the standard of a small and medium-sized alloy factory.

Documents of Equipment and Technical Files

- Operation and Maintenance Manual (O&M)

- The installation

- Equipment Layout

- The whole equipment installation manual, equipment installation drawing and requirements for water, electricity and gas.

- The external conditions (water, electricity and gas) required for installation of the sintering furnace shall be provided by the buyer according to the requirements of the supplier.

- Mechanical drawings

- Drawings of fragile parts of equipment

- Electrical Schematic Diagram

Buyer’s Preparation

- Prepared by the buyer before installation:

- Services required for hoisting and unloading sintering furnace equipment in place.

- The connection of the power supply to the connection point outside the power cabinet.

- The cooling water main inlet and return pipes connected to the equipment, various process gas pipes, compressed air and high-pressure argon supply pipes, high-pressure gas exhaust pipes, pump exhaust gas discharge pipes, etc.

- Supply and storage of pressurized gas and reduce the pressure of pressurized gas to the corresponding pressure range, the required equipment and the pressure reducing valve of each process gas.

- If necessary, measure the pollution of the pressurized gas.

- Emergency water supply device when cooling water is interrupted.

- The seller only provides certification materials for the production of pressure vessels in China. If other certifications are involved, the buyer shall bear the cost.

- The working medium, process materials and other related matters required for acceptance.

- Other unmentioned matters, which are not included in the scope of supply, shall be prepared by the buyer.

Design standards

The equipment is designed in accordance with the pressure vessel requirements of the Quality and Technical Supervision Bureau, and is qualified after pressure testing and shipped. The electrical design and construction meet national standards.

Horizontal and vertical options are available:

Disassembly and transportation

The equipment will be disassembled in several large parts, packed in a standardized wooden cases, and loaded into the transport vehicle.

Customer site installation and commissioning

The Redeer after-sales engineer will lead the team to complete commissioning, product trial burning and other work within 20 working days. The customer needs to make appropriate preparations and provide the necessary tools, such as hoisting and lifting equipment. And provide installation personnel support (it is recommended to have 1 mechanical personnel and 1 electrical personnel).

Final acceptance

After installation and commissioning, the equipment can be finally accepted in accordance with the requirements of the technical contract.

Training

Our after-sales engineers will provide a systematic and complete on-site training, including operation, maintenance, troubleshooting, etc.

Technical data delivery

To ensure safe operation and equipment maintenance, the following technical data will be provided to customers:

1. Equipment installation layout

2. User manual

3. Spare parts list

4. Electrical drawings

5. Component manual

FAQ

Q: Are you a factory or trading company?

A:We are China leading high-temperature vacuum furnace manufacturer with over 15 years’ experience.

Q: Do you have customization or OEM service?

A:Yes,we have powerful R&D team and high-tech equipment.So we can not only supply the regular model,but also the customizable furnace as the repuirment of our clients.

What's your advantage?

Q:What's your advantage?

A:

l Quick response to your enquiry

l High quality control

l Stable supply chain

l Timely delivery

l Excellent after-sales service

メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!  メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!